Markforged FX20

FX20™

An ULTEM™ Filament capable large format 3D printer for big, strong, high temp parts — usable from factory floor to flight.

The FX20 brings the Digital Forge and Continuous Fiber Reinforcement to a new realm of parts, problems, and industries.

Massive Builds, Faster |

Flight-Ready Functional Parts |

Production-Ready Performance |

|

The FX20 pairs size and throughput to make larger builds at incredible speeds, delivering the transformational benefits of The Digital Forge at a new scale. |

Built for everything from performance tooling and fixtures to flight-ready production parts — this large format 3D printer can reinforce ULTEM™ 9085 Filament with continuous carbon fiber. |

A precision-designed, sensor-driven production 3D printer delivers breakthrough reliability and performance with a simple user experience. |

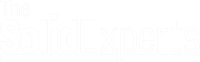

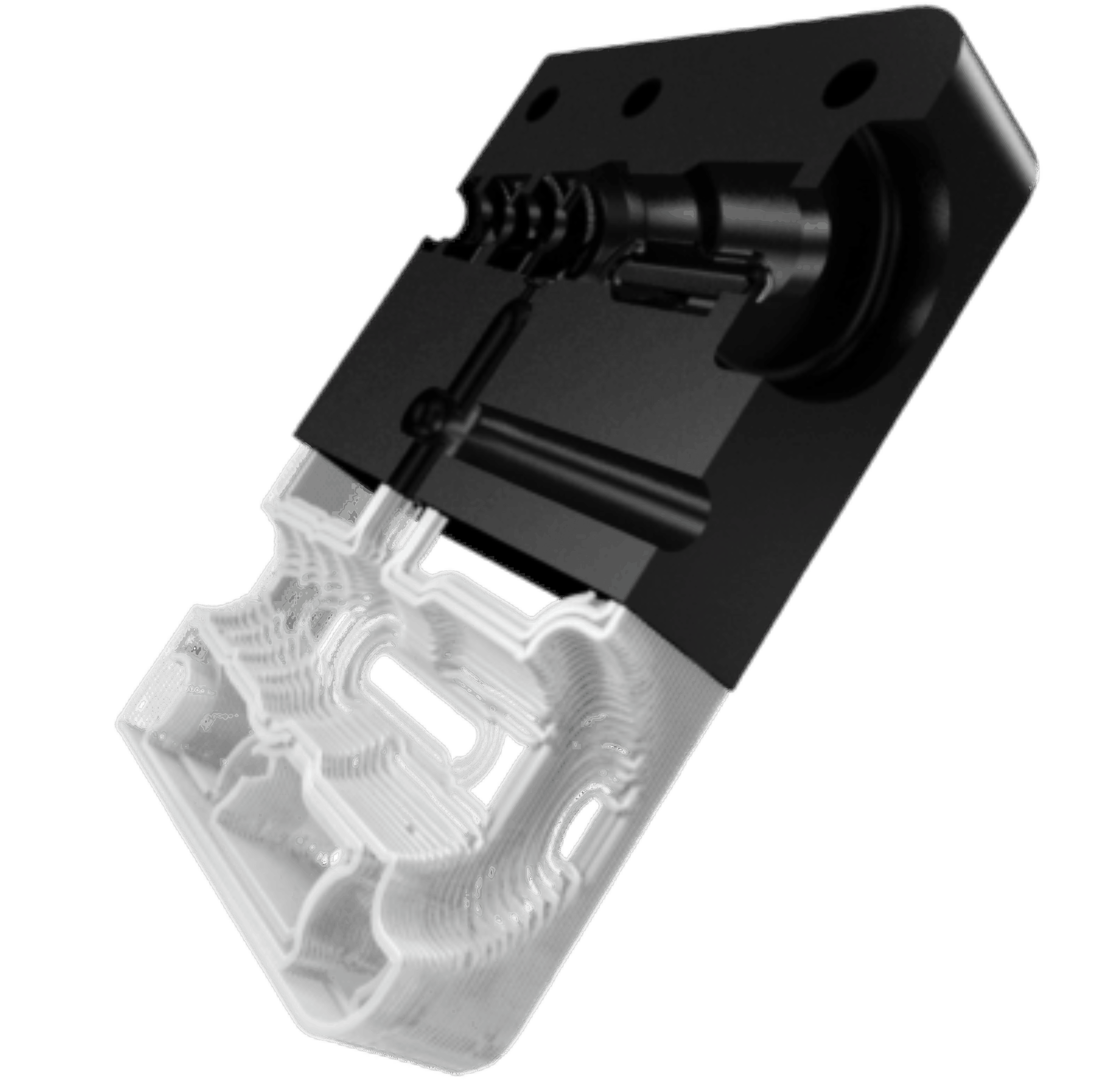

Composite 3D Printing Process

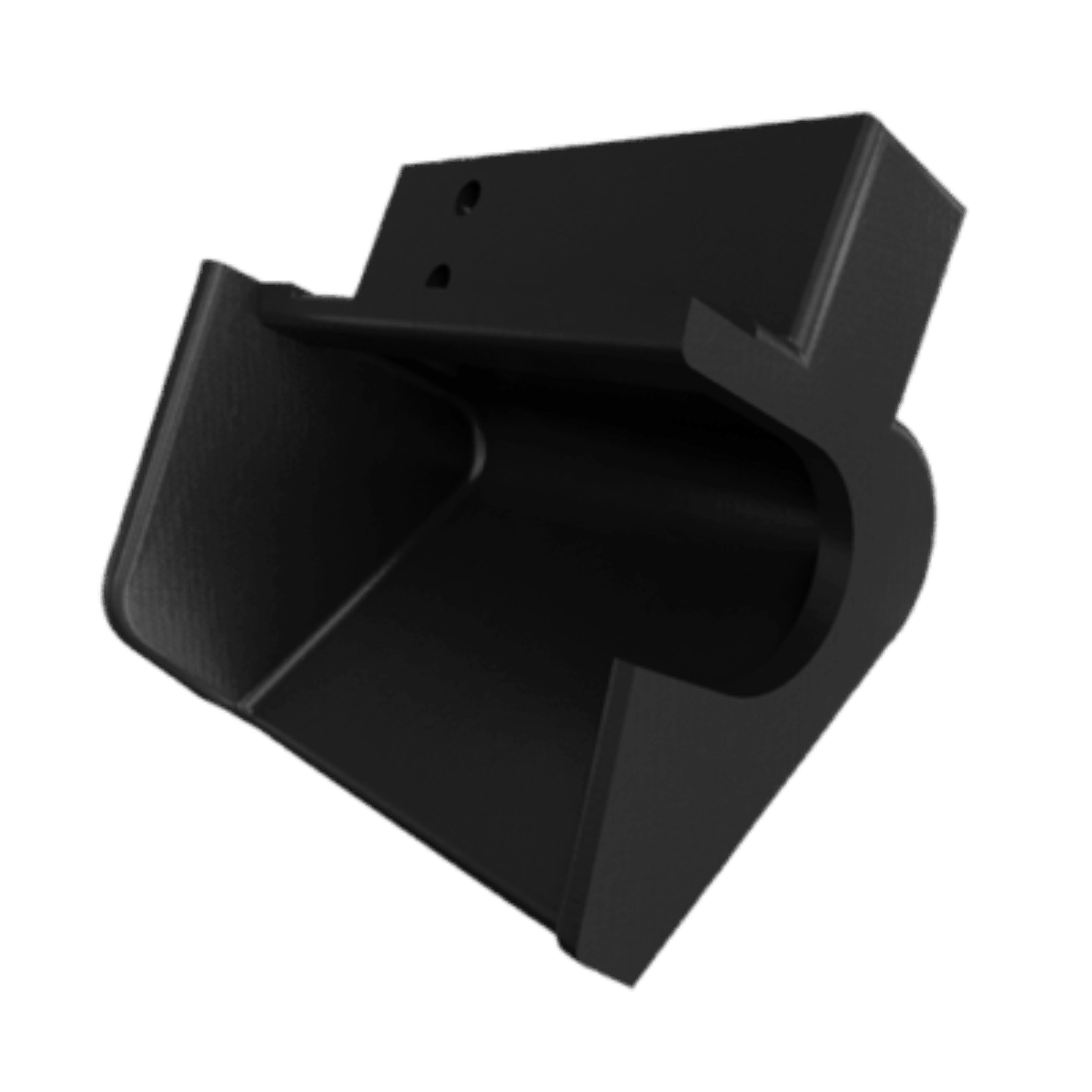

| Physical Dimensions | Build Volume |

| Width: 1325 mm | Width: 525 mm |

| Depth: 900 mm | Depth: 400 mm |

| Height: 1925 mm | Height: 400 mm |

| Weight: 530 kg / 1170 lbs |

Printing Process: Fused Filament Fabrication, Continuous Fiber Reinforcement (CFR)

Z Layer Resolution: 50 μm - 250 μm

Printing Media: Polymer Filament, Continuous Fibers

Internal Part Geometry: Closed Cell Infill with Continuous Fiber Reinforcement

Print Bed: Precision Machine Aluminum

Continuous Fiber Reinforcement, now with ULTEM™ 9085 Filament.

Carbon Fiber

Stiff, strong, and extremely light, carbon fiber reinforcement yields parts capable of replacing machined aluminum.

Carbon Fiber FR

Carbon Fiber FR is a flame-retardant flight-capable variant of Markforged's unique, ultra-high-strength Continuous Carbon Fiber. FR-A materials establish lot-level material traceability and pass the test suite necessary for qualification under 14 CFR 25.853 for most 3D-printable parts.

Continuous Fiberglass

Inexpensive and 11 times stiffer than ABS, Fiberglass is the perfect entry-level Continuous Fiber for 3D printing functional parts.

Aramid Fiber (Kevlar®)

Extremely durable and highly resistant to catastrophic failure, Kevlar® is an excellent reinforcement choice for harsh environments.

HSHT Fiberglass

HSHT fiberglass material delivers the highest impact resistance and heat deflection temperature of our continuous fibers, and can be used for low-temp molds.